Acoustic Fabric Cloth

Myths and information about acoustic cloth

Essentially, all materials have some kind of acoustic absorption and acoustic reflection at a certain frequency. This applies even to air…and clingfilm.

Material that is used to cover speaker cones/grill needs to be very very thin and provide no acoustic interference, at all, to the signal.

This is because the frequency response of a speaker is usually very precise, and flat, over a certain frequency range.

Our acoustic fabric cloth, however, are not specifically designed for this speaker application.

They are designed to be placed over acoustic absorption material to provide for a better aesthetic.

They are also used behind perforated panels which sit in front of acoustic material, again for better aesthetics.

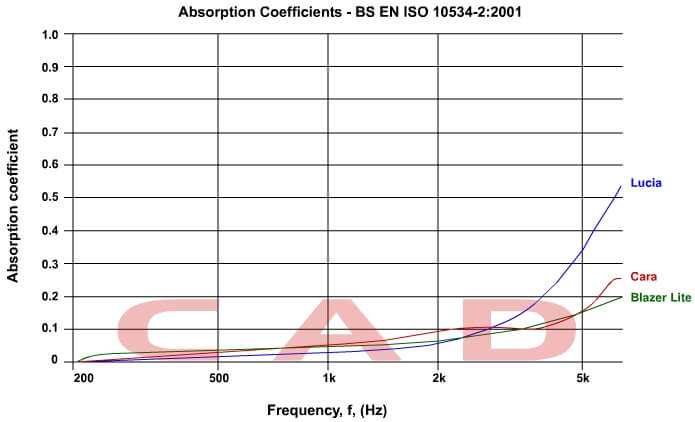

Some acoustic tests have been done to just measure the sound absorbing characteristics of the fabric on its own, as shown below.

Here we can see that there is negligible absorption until about 1kHz where there is about 5%, 2kHz up to 10% and 5kHz where it can be as much as 35%.

However, when the material is used over an acoustic absorber, this is beneficial and does not significantly affect anything acoustically.

Other tests have been done where the fabric has been placed on top of dedicated acoustic foam and measurements of the foam absorption before, and after, fabric placement have been conducted.

These tests show that at lower frequencies the fabric can add beneficial absorption which is mainly due to the changes of surface acoustic impedance, increased thickness (albeit very nominally), and the surface membrane effect caused by the fabric.

They can also show a reflection effect where the absorption of the foam, before the fabric is applied, was better than after the fabric has been applied.

Again, the differences are not significant enough to worry about in general real world applications.

Slight reflection at higher frequencies can be an advantage as it is often very easy to take too much high frequency sound energy from a space (whilst trying to reduce low and mid-frequency sound energy at the same time).

Other types of material such as leather, or very tight weave cloth, will allow for much more sound reflection as they would significantly block up the micro-pores of the absorbent behind as thus not be a good idea to use.

For applications using looser mineral fibers, especially where ceilings are concerned, there is sometimes a chance of fiber dust falling through the more open weave fabric if it is touched.

For situations like this we either suggest using two layers of fabric or we can laminate a 1-2mm thick grey polyester foam to the back…but the foam is not fire rated.

So to summarise…if you want to put this fabric over a speaker, you may need to tweak an EQ a little bit, to keep the response flat, but for the majority of other building acoustic applications it is generally easy for soundwaves to pass through it and into the acoustic absorbent material that does the main job whilst making it all look nice.

These fabrics are an open weave type and allow sound to enter acoustic products, materials and absorbers placed behind it.

These fabrics are not suitable for any soundproofing applications. Sticking this product directly onto a plasterboard finished wall will not be the solution to excessive reverberation within a room unless you have 25-100mm thick porous acoustic material behind it.

Our current ranges of acoustic fabric cloth are here.