Industrial noise barrier design.

Noise barrier design

Noise barrier design – Rules of thumb and things to consider if you think a noise barrier may be required as a solution to your industrial noise problem.

Generally it is best to engage an acoustic consultant if you have a need for an acoustic barrier or an acoustic enclosure.

Many common mistakes, or false assumptions, are made in respect of these pointers which can lead to their providing virtually no noise reduction at all.

A noise barrier design must at least block the line of sight between the noise source and the receiver.

For a ground level problem this may be fairly straight-forward, but if the problem involves say the second floor window of a building then things can get far more complicated and involved.

As long as it is wide enough this can give an insertion loss of 5dBA but it is best if it is at least 30% higher than this where it could achieve a 10dBA insertion loss.

A sound barrier must have enough mass so that the noise is forced over it and not through it.

This would generally be in the region of 15-20kg/m².

The frequency and wavelength of the problem noise needs to be taken into consideration. There are also other paths around a noise barrier which may include the sides.

A properly designed barrier can give an extra 1dBA for each extra meter of height, over and above the direct line of sight.

A barrier should be placed as close to the noise source as possible.

A noise barrier may require an absorptive (rather than reflective) face. This will depend on the noise problem between the source and receiver.

A noise barrier is unlikely to give more than a 20dBA insertion loss.

A noise barrier design needs to be wide enough. It should be 8-10 times as long as the distance between the receiver and barrier itself. The receiver position needs to be central to the barrier length.

Noise enclosures should not be tight fitting. Space is required around the noise source inside depending on its frequency content.

What works in one application may not work in a different application. Generally no two situations are identical in every way.

In a factory environment a simple noise barrier may help with reducing noise to another operator close by.

However, depending on the reverberation times, height of the factory and room constant it may not provide any satisfactory noise reduction for operators at a distance away from it.

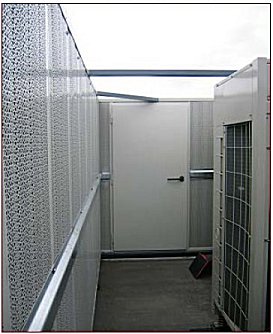

An ideal modular noise barrier solution is our AC80 Modules.

These form part of a modular system which is easy to install onsite with the associated fixing trims and are rated at up to 32dB. They have a Class A internal acoustic absorption face to reduce the noise energy buildup.