Sound Transmission Loss

Sound transmission Loss and how to improve it

It is very important to distinguish between sound absorption and sound transmission loss.

Sound absorbing materials control sound within spaces and function by allowing sound to pass through them relatively easily.

They are generally porous and absorb sound as a result of many interactions.

Conversely, a material or system, that provides a good sound transmission loss is usually non-porous and a good reflector of sound.

For significant noise reduction between rooms, the walls or floor, separating them must transmit only a fraction of the sound energy striking them.

The ratio of the sound energy striking the wall to the sound energy transmitted through the structure is called transmission loss and expressed in decibels.

The sound transmission loss of a basic construction can be improved by:-

- increasing mass

- breaking the sound vibration path

- increasing cavity depth

- providing cavity absorption

- increasing damping

Improving sound transmission loss by Increasing Mass

Heavier materials block sound better than light materials. For example, adding another layer of plasterboard provides increased sound transmission loss.

As a general rule, every doubling of the weight of the wall increases sound transmission loss by an additional 5-6dB. Heavier walls, however, are not the most economical or practical solution to sound control.

It should be noted that lightweight blockwork has poorer sound insulation values at low frequencies because of its porous nature. These types of blocks must be plastered (preferably both sides) to achieve satisfactory sound insulation.

Plasterboard must be butt jointed at the studs only. Layers should be ‘staggered’ so that the joints do not ‘overlap’.

All joints must be sealed with plaster at each stage. All edge peripheries must be sealed, with mastic, at each stage.

If bricks are used which have ‘frogs’ they must be bedded in mortar with the frogs uppermost to ensure that the wall is solid, and filled, throughout.

Improving sound transmission loss by Breaking Vibration Paths

Walls transmit sound most effectively when they can transmit vibrations from one wall face to the other through structural elements such as the studs.

Whatever can be done to interfere with the transmission of vibration between one wall surface and the other will help reduce sound transmission through them.

Metal studs are more resilient than wood studs and reduce the transmission of vibrations between one wall surface and the other.

In wood stud constructions resilient metal bars can be used between the plasterboard and the studs to break the vibration path.

Although the rules for maximising sound control are relatively simple, applying them is not.

The theory underlying these rules is not well understood in the ‘trades’, and the opportunities for error are innumerable.

Improving sound transmission loss with Cavity Absorption

The sound transmission loss of a wall can also be increased by filling the wall cavity with sound absorbing materials such as acoustic mineral wool insulation.

Care must be taken to avoid bridging any cavities in such a structure.

Cavity infill has the added advantage of keeping the cavity clean of mortar droppings.

It takes only 1 lump of mortar, bridging the cavity, to ruin the elaborate precautions taken to optimise the sound insulation in the first place.

Perimeter Sealing

An air-tight seal should be used around the perimeter of the wall or ceiling to effect a proper acoustic seal.

This is critical. DO NOT under-estimate the amount of sealing mastic you will need for an acoustic partition

A wall with a potential Rw of 55 or 60, which has a hole of only 0.001% of the total wall area, is reduced to an effective Rw of 50.

As the hole area increases, the rating is eventually determined entirely by the hole area.

The higher the acoustical isolation that is sought, the more important it is to eliminate all sound leaks

Such tiny leaks can easily occur at the periphery of walls and floors, where caulking is absent or improperly done, or where a hole is made to add some service such as electricity or plumbing.

To reduce sound leaks, all holes and fissures in a party wall or floor must be thoroughly caulked, all windows and doors must be tightly weather-stripped, and holes for services properly repaired.

As a rule of thumb, if a construction is not watertight, then there is a good chance it is not ‘sound-tight’.

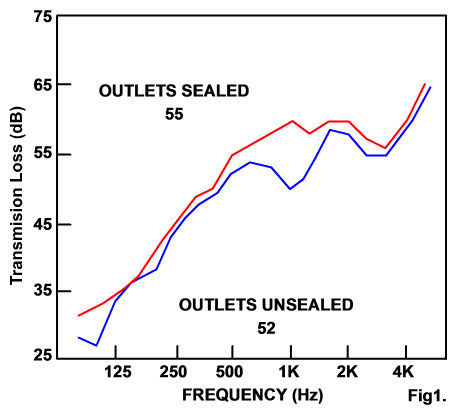

As a practical example, Fig1. shows the effect of back-to-back, improperly sealed electrical outlets on the Rw for a wall.

Sealing the outlets properly increases the Rw from 52 to 55.

In this case, although the holes were rather large, the presence of glass fibre in the cavity helped to reduce transmission through the leak. This is one advantage of using sound-absorbing materials inside wall cavities; because of the losses in the sound absorber, the transmission loss of the hole is no longer zero.

Nevertheless, if electrical outlets must be installed in a party wall, they should be offset from each other along the wall, as well as being correctly sealed.

It is common to see structures that start to leak sound over time. This is because the wood components have shrunk enough to create a small crack, often where insufficient amounts of mastic have been carelessly applied in the first place.

Doors

Where optimum noise control is desired, solid wood core doors should be used.

Frames should ideally be 125mm x 75mm hardwood firmly bedded in mastic.

Many times we have looked at an sound problem with a door only to find that when the architrave was removed the entire frame had a few wedges and a good 10mm gap all the way around the perimeter.

Door heads, jambs and thresholds should be sealed with at least basic draught seal.

Windows

Windows usually have a much lower transmission loss value than the surrounding wall.

It is advantageous to reduce window area for increased noise control. Glass, in sound insulation terms, obeys the ‘Mass Law’ which projects a linear relationship between mass per unit area and the sound reduction index between the limits of:-

- resonant frequency at the lower end and

- critical frequency at the upper end

The thicker the glass, the more effective it is as a noise barrier for single glazing. A single pane window has an SRI of around 25dB.

Double glazing provides a slight improvement on single glazing.

Standard double glazing with a 12mm air-gap will have a high resonant frequency, due to the small gap and low mass, which dramatically reduces the sound insulation around that point.

Standard double glazing will give an improvement of about 4dB over a standard window.

To improve significantly on single glazing, an air-gap of at least 100mm to 300mm should be included. To reduce inter-panel resonance effects the panes of glass should ideally be of unequal thicknesses by a difference of 30%-50%.

Electrics

Light switches and outlets should NOT be constructed back-to-back. Ceiling fixtures should be surface mounted and openings around boxes should be sealed air-tight.