Vibration Natural Frequency

Description

Vibration natural frequency – A materials natural frequency is described as the rate at which is will vibrate, when disturbed by an external force, but without being subject to a further driving or damping force.

A typical example is a bell or a tuning fork.

If a bell is struck it will vibrate at a particular frequency and will decay slowly to a stop. If a tuning fork is struck it will easily stop vibrating if the damping force of two fingers is applied to it.

Both have a natural resonant frequency which, through amplification, produces that particular tone.

Typical Performance

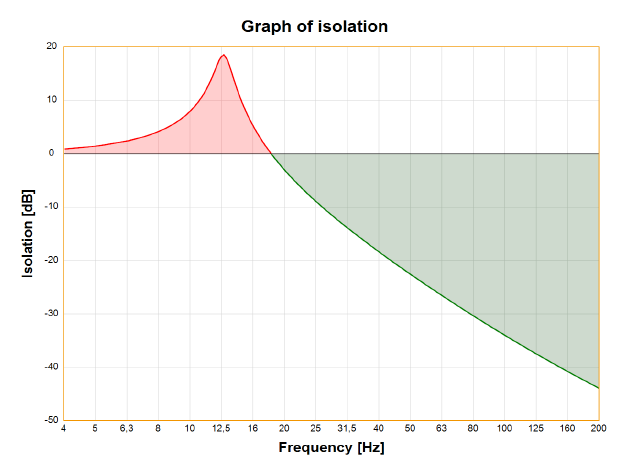

The graph below is a typical example that will often be seen on data sheets with respect to an anti-vibration products and how they perform.

It shows a vibration natural frequency of about 13Hz for the material in question. (The peak in the red line)

This does not mean that at 13Hz maximum vibration isolation will be found, rather the opposite.

At 13Hz this material amplifies vibrations. The red area of the graph is amplification.

It is only when the materials internal damping comes into force that it will provide for vibration isolation.

In this example it starts doing this at about 18Hz.

The green area shows the frequencies where it will work for damping vibration.

Physical Properties

There are many physical properties of a vibration isolation material that all interact with each other to produce a specific end solution.

With respect to specifically designed, and efficient, anti-vibration dampers, pads, springs etc the thicker and stiffer the material, the lower the natural frequency will be.

As an example, a vibration isolation pad may have a natural frequency of 17Hz in a 12mm thickness but 11Hz at 25mm thick.

Deflection

Deflection describes how much a material will deform under a load. If a vibration pad is 25mm thick with no load then adding some weight loading on top of it will compress it somewhat. This difference in thickness due to compression is referred to as its deflection.

There are two types of deflection. Static and dynamic. An acoustic floor for example may have a static load, due to the weight of the concrete, of say 10,000kg but when people are walking over it and then sitting on chairs the overall floor weight will increase and may not even be the same all the time. It may vary.

As a generalisation, the more deflection the lower the natural frequency will be.

As an example, 80kg applied to a 25mm thick pad may produce a deflection of 2.6mm but the same mass applied to a 12mm pad may only produce 0.5mm deflection and hence a higher natural frequency.

Loading

Loading/mass/force refers to how much exertion is being applied to the material to compress it. Here things can get a bit confusing.

Load is often referred to in N/mm2 (Newtons per mm squared)

Mass is often referred to in kg (kilograms)

Force is often referred to in kN (kilo Newtons)

With some fancy maths all of the above can be related to each other and calculated.

Capacity

A material, or a spring, will only be able to take a certain amount of compression before it fails to work. A spring may even snap. It is important that any anti-vibration component is not overloaded. Many materials, once they fail, cannot recover again and so become useless.

The load limit of a product must be known and must never be exceeded.

Conversely, the material needs to be at a high capacity to provide its best performance. If it is used under its ideal capacity then the natural frequency will be higher and acoustic isolation will not be optimised.

Lets take an example of a pad optimised for 80kg but only place 40kg on top:

Capacity: 50%

Deflection: 1.3mm

Natural frequency: 16Hz

Size

Size is important. For example, lets take a 50x50mm isolation pad with a static load limit of 81kg and sit an item of 80kg on top of it. We have the following characteristics:

Capacity: 99%

Deflection: 2.6mm

Natural frequency: 11Hz

If we were to double the size of the pad this could cause all sorts of problems.

Firstly, doubling the pad size would increase its static load limit from 81kg to 172kg and with the same 80kg applied we would find things have changed to:

Capacity: 47%

Deflection: 1.2mm

Natural frequency: 17Hz

Vibration Natural Frequency & Rule of Thumb

As all of the terms mentioned above all interact with each other a handy rule for selecting vibration isolation mounts is to choose something that fits the application, can be installed conveniently, will not exceed the load capacity, has the natural frequency as close to the ideal as possible but keep the loading to at least 80% (if possible).