Menu

![]() A Revit / BIM Family object file is available for this product.

A Revit / BIM Family object file is available for this product.

USES |

|

BENEFITS |

|

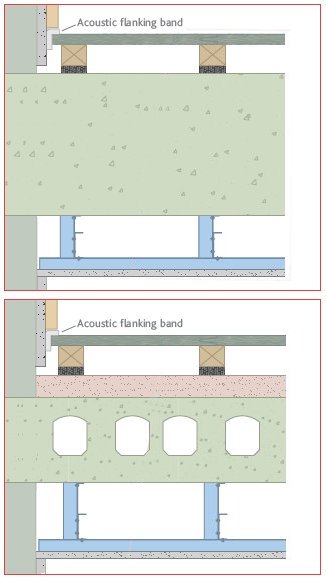

The Ecocheck shallow batten system is designed to reduce sound transmission through a concrete structural sub-floor and consists of a layer of 13mm LRC foam bonded to a softwood batten.

When installed as part of a complete party floor construction it enables a concrete floor to meet the sound transmission standards of ADE 2003 (amended 2004). Should the requirement be for a batten height other than that detailed on this page please contact us for further advice of suitability and availability.

– Overall batten size: 1800mm x 45mm x 45mm*

– Resilient layer thickness: 8mm

– Resilient layer: X-link Isopol

* alternative batten depths are available to special order.

Treated floor meets with the descriptive FFT3, typically within Robust Detail E-FC-2. Using deeper battens (min. 70mm) would conform to FFT1 within E-FC-2 and E-FC-7.

Treated floor meets with the descriptive FFT3, typically within Robust Detail E-FC-1. Using deeper battens (min. 70mm) would conform to FFT1 within E-FC-1 and E-FC-7.

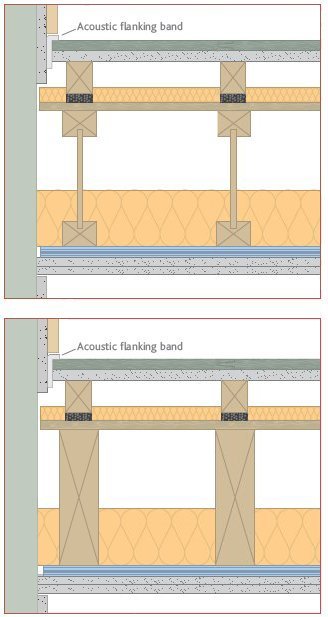

EcoCheck Deep Batten system is designed to reduce sound transmission through timber floors within a timber framed structure.

EcoCheck Deep Batten consists of a batten bonded to 15mm LRAC. When installed as part of a complete party floor construction it enables a timber floor to meet the sound transmission standards of ADE 2003 (amended 2004).

Should the requirement be for a batten height higher than that detailed here please contact us for further technical advice and suitability.

– Overall batten size: 1800mm x 45mm x 75mm OA

– Resilient layer thickness: Down to approx. 13mm under normal domestic load

– Resilient layer: 15mm LRAC

Treated floor meets with the descriptive FFT1, typically within Robust Details E-FT-1 and E-FT-2 and E-FT-3.

Treated floor meets with the descriptive FFT1, typically within Robust Details E-FT-1 and E-FT-2 and E-FT-3.

This flooring system performs best when the flooring perimeter is kept isolated by using acoustic flanking strips.