Menu

They have a rigid, acoustic-rated fibreglass core with a Class 1 fabric covering as standard, available in a wide selection of colours. Class 0 fabric is available at additional cost.

Select from our standard fabric ranges – CARA – (Class1 FR) or LUCIA – (Class1 FR)

For panels suspended from the ceiling we supply a fully adjustable wire system with 2m cables and spiral springs.

For wall-mounted panels we supply spike plates and spray adhesive.

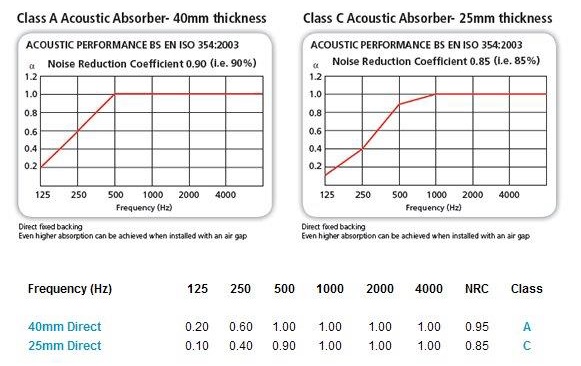

We offer two thickness options: 25mm which is Class C; and 40mm which is Class A.

These acoustic panels weigh 4.5kg/m2 at 40mm thickness.

When ordering panels please advise us if you need fixings. Panels are supplied without them unless specifically requested. Certain types need to be specified in advance. There will be an additional cost for supplying various clips, glues, chains, wires, battens etc. If you are unsure about what to use please contact our Technical Department

Wall Spike Installation

Wall Spike InstallationMetal impaling clips are screwed into the wall.

This method does not allow easy removal of the panels.

For smaller panels spikes can be used without adhesive so the panels can be removed. However, this does not provide a permanent fix so would not be suitable in areas such as schools.

For ceiling mounting the panels are supplied complete with spiral hooks, and 2m cables with adjustable height clutch for each adjustment.

The installation image to the left is not to scale and should only be used as a guide.

The spiral hooks should be 200 – 300mm in from the panel edges (the larger the panels, the further in from the edge the hooks need to be) to prevent uneven load distribution which, over time, could cause the panels to bend. If the suspended wires are too close to the panel edge they will be clearly visible, as well as creating slight sagging. If in doubt contact our technical department.

View more examples in our Projects Section