Menu

Uses:

|

Benefits:

|

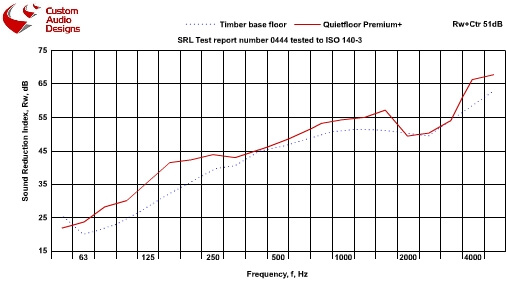

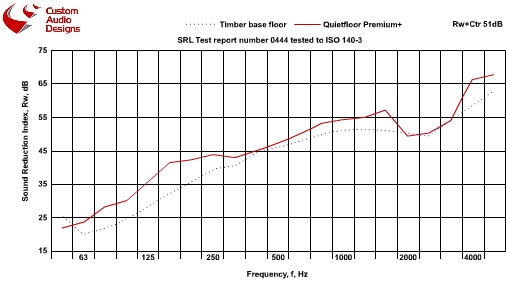

Quietfloor Premium+ Acoustic Underlay is a superb acoustic floor system designed to reduce both the impact and airborne noise transfer through floors.

Adapted from an industrial product that was originally designed to greatly reduce the sound transfer of plant machinery noise through floors.

General Physical Data |

|

| Sheet Size | 1200mm x 1200mm |

| Thickness | 15mm |

| Weight | Approx. 16Kg/m² |

| Flammability | |

| Foam | (FMVSS 302) – Self-Extinguishing |

| Barrier | (FMVSS 302) – Self-Extinguishing |

The laminated composition provides maximum performance for minimum thickness and combines excellent sound insulation with all the qualities of a good carpet underlay. Consequently, it is quick and easy to install and is easily cut and shaped. Overall thickness is just 15mm so it minimises the increase in floor level.

This product comprises a 10mm layer of chipfoam bonded between 2 layers of 7.5kg/m² mineral loaded acoustic barrier matting. The base layer of barrier mat seals and damps the sound coming through the floor, the isolated top layer of soundproofing mat blocks the sound both ways. Additionally the chipfoam core reduces impact noise transfer.

This product also gives superb performance when used as floating floor isolation under a T&G chipboard wooden topfloor.

Averaged on-site tests have achieved the following results:

Lathe and plaster ceiling, no cavity insulation, no 9mm board ontop: 43dB L’nT,w.

Lathe and plaster ceiling, 100mm cavity insulation, with 9mm board ontop: 59dB L’nT,w.

Resilient bar double boarded ceiling, 100mm cavity insulation, with 9mm board ontop: 54dB L’nT,w.

Averaged on-site tests have achieved the following results:

Lathe and plaster ceiling, no cavity insulation: 43dB DnT,w+Ctr.

Lathe and plaster ceiling, 100mm cavity insulation: 45dB DnT,w+Ctr.

Resilient bar double boarded ceiling, 100mm cavity insulation: 50dB DnT,w+Ctr.

Before laying Quietfloor Premium+ Acoustic Underlay you should examine the existing floorboards. Whenever any are loose they should be firmly secured down. Additionally, it is also wise to replace any sections that are damaged or broken. Furthermore, it can also be beneficial to seal the gaps between the floorboards and overlay with VL65 Acoustic Membrane for improved performance first.

Quietfloor can be simply laid, or bonded, to the floor. It is essential that the sheets are laid in a staggered, brick type pattern, and that they are butted tightly together, and up to the perimeters of the room. Due to the 15mm thickness it is best to first run a 9mm thick timber batten, the same width as the grippers (about 25-30mm wide), around the room perimeter. The grippers can then be nailed into this raised batten.

Please note: If your subfloor is not level then you will need to bond the sheets down to prevent any subsequent lifting due to bowed flooring. In older properties even if you have leveled out a floor using chipboard it is still possible that the small irregularities are dealt with but the overall floor may rise and fall in line with the old joists. Small sheet material may want to ‘lift’ in certain areas if it is not bonded down.

Once complete, aluminium foil tape is ideal for sealing the joins between sheets.