How to Soundproof Industrial Machines

How to soundproof industrial machines

Machine noise can often be a problem and the best way to deal with this is to cover the unit with a soundproof enclosure.

The enclosure itself needs to be fabricated from heavy materials to block the noise and an absorbent lining will improve things further by reducing the amount of reverberation build up inside the box.

Structural contact between the enclosure and the machine must be avoided otherwise the vibrations will be transmitted to the enclosure walls and re-radiated outside.

If the noise is structure-borne then vibration isolators can help but these will generally only reduce the low frequency components below around 100Hz from transmitting into the building.

Materials such as our Pyrosorb Duct Foam or Foam/Barrier Composite can be applied inside smaller units to reduce reverberation and block sound/damp vibrations to reduce the overall sound output.

If the enclosure has a roof covering dense mineral fibre can also be used as the internal absorbent material.

This sort of enclosure may be constructed from something like steel or heavy timber.

Materials such as our Visco-elastic Damping Membrane VL-65 can be applied to vibrating surfaces to reduce the overall sound output.

Partial Enclosures

In some cases it may be sufficient to utilise just a partial enclosure. This may be two sided in the shape of an ‘L’. It may be a ‘tunnel’ open at each end. It may or may not require a roof.

These solutions will not provide the same degree of insertion loss as a full enclosure but may meet the requirements.

Usually acoustic calculations can determine which option would be most efficient.

It is important to consider airflow requirements so the unit can breath and not overheat.

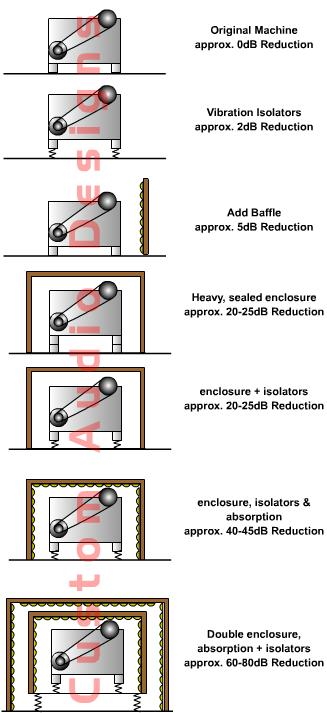

The following diagrams show the design and effectiveness of various machine enclosures:

Larger machine enclosures

For larger machine enclosures or plant rooms it is more effective, and easier, to utilise steel perforated acoustic lining panels such as our AC50

These are easy to install, easy to cut and frame around openings using the supplied fixing trims. They provide for a ClassA acoustic absorption and are robust and fire rated.

In some situations a separate acoustic enclosure may be required. This may be to provide for a noise haven or control room for workers in a noisy environment or to house a single noisy machine.

As opposed to lining a large plant room with acoustic panels a more efficient solution may be our steel perforated AC80 panel system which is not only modular, but self contained and can incorporate acoustic windows, doors and silencers for ventilation.