Menu

An Industrial Noise Barrier panel or acoustic barrier solution in a modular format. With this noise barrier system there is no need for expensive bespoke manufacture. Noise Enclosures or acoustic barriers can be constructed on-site using the modular steel sections which are easy to configure.

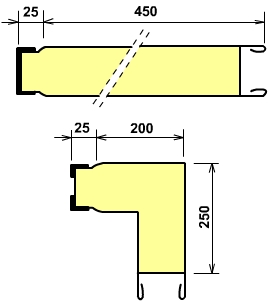

The panels consist of a pre-lacquered metal sheet of 1mm thickness (light grey similar to RAL 9002) with a 70kg/m³ acoustic mineral wool infill, covered with a black scrim tissue facing, behind a 0.5mm multi-perforated steel sheet.

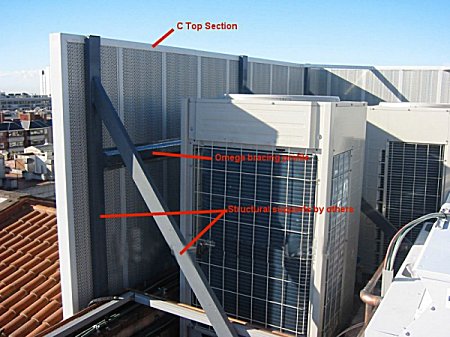

A supporting frame is almost always required. The supporting framework needs to be able to accommodate any significant wind loadings that may be experienced. The distance between the supporting steels will depend on height and other factors but is usually no less than 1800mm centres and no more than 3000mm centres.

The panels are T&G so slot together using the proprietary trims.

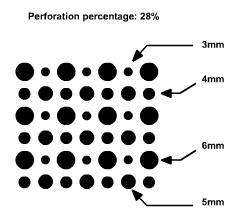

The perforation percentage for the face of these panels is 28%. Each panel has five different kinds of perforations diameter.

Non perforated corner units can be used for both internal and external corners.

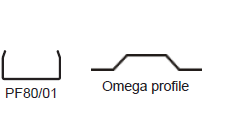

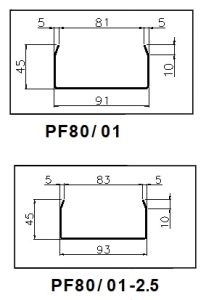

If these panels are being used for an internal acoustic enclosure then the 1.2mm thick profiles are generally adequate. However for external application, and especially for welding, the thicker 2.5mm PF80/01 and Omega profiles should be used as the thin profiles cannot accept welds.

For internal use for machine noise enclosures we can supply acoustic doors and windows which simply slot into place as the panels do. If ventilation is required we can supply vent systems. Generally small machine noise enclosures do not require any additional support framework but for external use as noise barriers then an internal or external support structure will be required. This may need to take into account wind loadings so it is best to consult with a structural engineer on these matters. Often support braces are required every 2-3m or so.

Made of 1.2mm pre-lacquered galvanised smooth sheet metal shaped to be assembled with the panels. Maximum length is 3000mm. Special thickness of 2.5mm for barriers and special installations which require welding.

The PF80/01 ‘U’ channels are fixed to the base, the main panels slot into this profile. The same PF80/01 can be used to cap off ends or the top. The Omega profile acts as a central ‘brace’ which. at 2.5mm can be welded to. Screw fixings to use are generally Wurth facade self tapping.

SPECIFICATIONS |

|

| Finish | Light grey (similar to RAL9002) |

| Thickness | 80mm |

| Weight | 21kg/m2 |

| Panel lengths | 2000mm, 2500mm, 3000mm or 4000mm |

| Perforation percentage | 28% |

| Finishing | Rockwool with black tissue |

| Youngs modulus | E=210.000 N/mm2 |

| Fire resistance | B,s1,d0 (Class 0) |

| Max. allowable working stress | σ=224 N/mm2 |

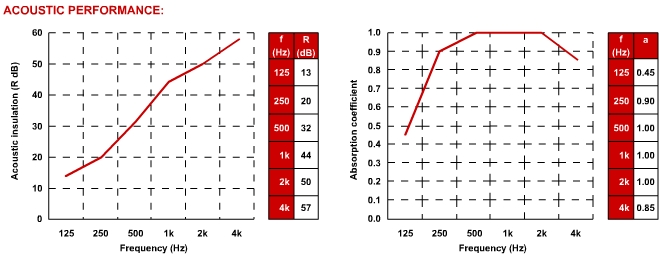

| Acoustic absorption αw | 1.00 |

| Acoustic insulation | Rw 32dB |

| DLR | 26 dB – Category B3 |

| DLα | 15 dB – Category A4 |

| Absorption Class | A |

View more examples in our Projects Section