Menu

Rubber cork acoustic underlay mix EcoMat RC3 and RC5.

Suitable for:

|

Benefits:

|

Rubber cork acoustic underlay EcoMat RC3 and EcoMat RC5 acoustic matting is a Document E compliant resilient layer, suitable for use as acoustic matting under most floor finishes such as ceramic tile, stone, vinyl, wood, carpet etc.

The material is manufactured from waste rubber and cork which is mixed with a polymer binder to form a purpose made resilient acoustic matting which has exceptionally good insulating qualities.

The RC matting has been developed for use in both commercial and residential buildings such as apartments, hotels, hospitals etc. EcoMat RC3 and EcoMat RC5 has been developed to meet the current Building Regulations and is Document E compliant. It combines minimum build height with permanent resilience.

Impact Sound Insulation:

EcoMat 3mm Δ LW18dB

EcoMat 5mm Δ LW20dB

Measured in accordance with BS EN ISO 140-8 1998

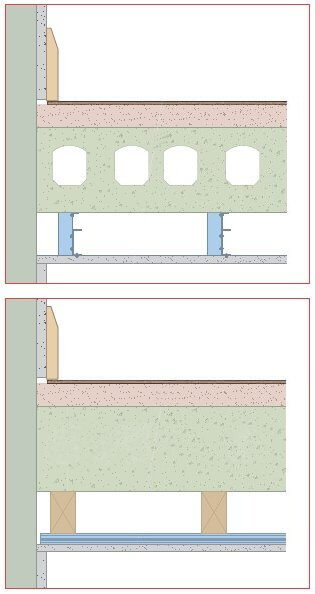

Detail

Detail

General physical data |

|

| Roll size | 1m x 10m |

| Thickness | 3mm or 4.5mm |

| Density | approx. 730kg/m3 |

| Flammability | B2 |

| Colour | Black/beige/mixed |

| Tensile strength | >700KPa |

| Castor chair suitability | Yes |

| Compression | 17%-20% |

| Recovery from Compression | >85% |

| Tog Rating | 0.75 |